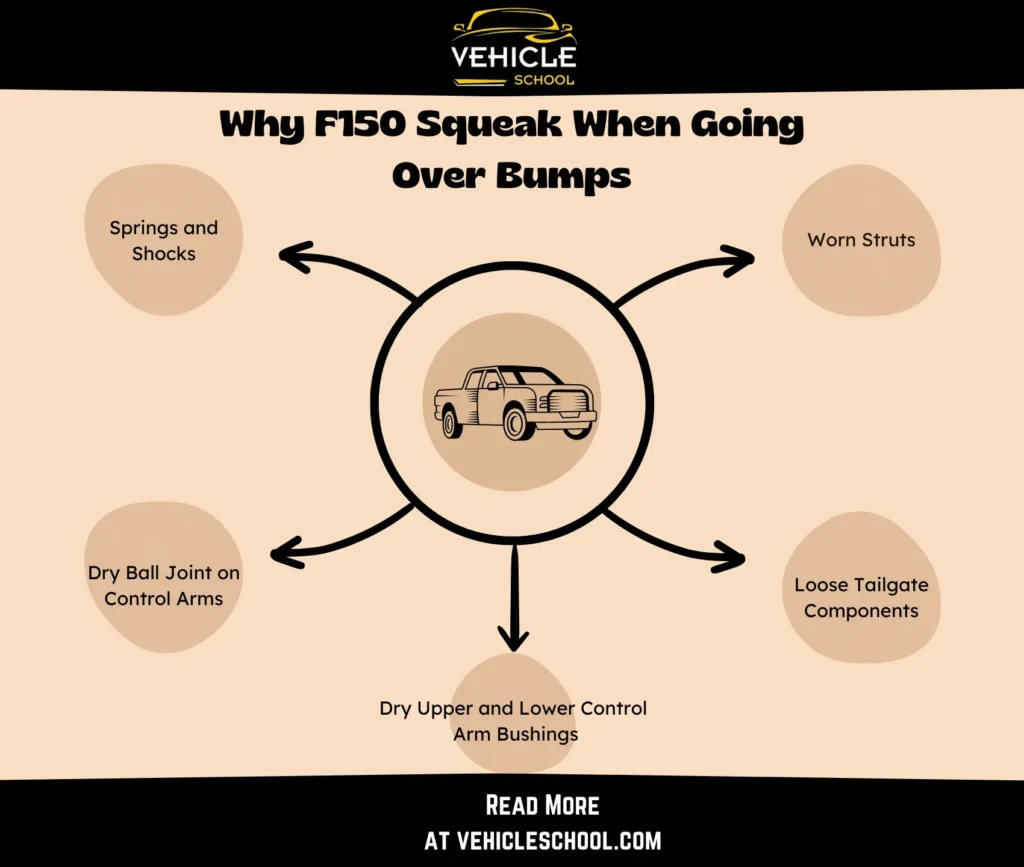

The squeaking noise F-150 makes when going over bumps indicates worn struts, neglected tailgate parts, or dry components. You have to lubricate the struts, check the tailgate, grease the shocks, ball joints, and control arm bushings, or replace worn parts to get rid of the noise.

If you’re not sure how to do all that, keep reading my post for detailed instructions.

Why Does Your F150 Squeak When Going Over Bumps?

Let’s start by going through all the reasons why this happens:

1. Worn Struts

The struts in an F-150 go through a lot, dealing with the weight of the truck and the challenges of the road.

As time goes on, the internal parts wear down, and the fluid that keeps things moving smoothly can wear out or leak.

This wear and tear makes the suspension system less effective, leading to squeaky sounds when you hit bumps on the road.

2. Loose Tailgate Components

Your F-150’s tailgate can start making noise when you go over bumps if the hinges and latch points aren’t properly aligned.

Regular use, exposure to different weather conditions, and the fact that tailgates often get overlooked in maintenance can cause metal-on-metal friction, resulting in annoying squeaks when you encounter bumps.

And if you’ve recently added an aftermarket tailgate step and forgot to tighten the screws, that might also be why you’re hearing squeaks when going over bumps.

3. Springs and Shocks

The springs and shocks are vital to your F-150’s suspension system.

Without regular TLC, dirt, grime, and moisture can build up on these moving parts, increasing friction.

This, combined with a lack of proper lubrication, is a recipe for squeaky sounds, especially when the springs compress or the shocks do their thing over bumps.

4. Dry Ball Joint on Control Arms

The ball joints on your F-150’s control arms allow for flexible movement in the suspension, but they can get dry over time, losing their lubrication.

This dryness creates more friction between the ball and socket, leading to squeaks, particularly when you’re rolling over bumps or rough patches on the road.

5. Dry Upper and Lower Control Arm Bushings

On 2WD F-150s, the upper and lower control arm bushings can dry out, thanks to exposure to the elements.

This dryness means more friction and less flexibility, resulting in those irritating squeaks when the control arms move in response to bumps.

How To Fix Squeaky Noise F150 Makes When Going Over Bumps?

Here are all the permanent and temporary fixes you can try:

1. Lubricate The Struts

- Confirm squeaking from the struts by listening during bumps.

- Wipe the struts clean to remove debris.

- Apply silicone lubricant directly to moving parts.

- Bounce each corner of your F-150 to distribute lubricant.

- Drive gently to reduce stress and provide temporary relief.

2. Replace The Struts

If you’re hearing the noises coming from your rear struts, just follow the below:

- Lift the truck and remove the wheel.

- Apply penetrating lubricant, remove nuts, and disconnect components (lower strut, tie rod, sway bar link, and upper ball joint).

- Pry down and remove the old strut.

- Apply red thread locker to new strut studs and install.

- Secure the strut to the lower control arm and torque all nuts.

- Reconnect the tie rod and sway bar link, and secure the upper ball joint.

- Snug up and torque the strut-to-strut tower nuts.

- Reinstall the wheel, lower the truck, and torque lug nuts.

3. Inspect Tailgate

- Open the tailgate access panel.

- Locate the green rod connector.

- Tighten/pull the green rod connector slightly.

- Test the tailgate by closing and reopening it to check for squeaks.

4. Lubricate The Shocks

- Lift your F-150 safely with a jack for access.

- Find the squeaky shock.

- Use Liquid Wrench lithium grease or WD-40 with a spray nozzle to generously apply the lubricant.

- Ensure thorough coverage on all areas where metal parts may rub.

- Consider removing the wheel for extended access.

- If you are concerned about protecting wheels or brakes, use a plastic bag around the brake area before spraying.

- Pay attention to detail and spray all parts for effective lubrication.

- Repeat this for all shocks, even those not currently squeaking, as a preventative measure.

5. Grease Ball Joints

- Inspect and replace damaged dust boots.

- Clean the grease zerks.

- Identify front-end grease points.

- Lift your truck if needed for better access.

- Use a flexible hose grease gun for angled zerks.

- Grease lower ball joints.

- Remove the wheel if necessary for the upper ball joints.

- Grease-tie rod ends.

- Grease stabilizer joints and check for hidden zerks.

- Look for extra grease points on steering components.

- Rotate the wheels for thorough greasing.

- Wipe away the excess grease.

6. Grease Control Arm Bushings

- Grab a silicone-based spray.

- Lift the vehicle.

- Spray generously on upper and lower control arm bushings.

- Bounce the truck to spread the spray.

- Test drive to check if squeaks over bumps are gone.

7. Replace The Bushings

- Remove the securing nut.

- Disassemble connected components.

- Support the vehicle with a jack.

- Undo the nut or bolt to drop the bushing.

- Remove old bushings and related parts.

- Apply lubricant to the new bushing if needed.

- Install new bushings, ensuring proper alignment.

- Reattach the disconnected components.

- Tighten the securing nut or bolt.

- Torque as recommended in your F150’s manual.

8. Replace The Lower Control Arms

- Remove wheel and disconnect the caliper, ABS wire, and vacuum hose.

- Unbolt outer tie rod and upper ball joint.

- Remove axle nut and lower strut bolt.

- Disconnect sway bar link and ABS wire.

- Install new control arm and torque bushings to 258 ft-lbs.

- Tighten lower strut bolt to 406 ft-lbs.

- Secure sway bar link and reconnect the ABS wire.

- Reassemble the knuckle, axle, and ball joints.

- Torque upper ball joint nut to 85 ft-lbs and the lower ball joint nut to 111 ft-lbs.

- Reinstall axle nut, rotor, and wheel.

- Torque lug nuts to 150 ft-lbs in a cross pattern.

- Pump the brakes, take a road test, and see if the squeaky sound is gone.

9. Replacing Upper Control Arms

- Lift the vehicle and support it on axle stands.

- Disconnect sway bar end link, ABS wire, and strut.

- Remove upper control arm by releasing the silent block screws.

- Install the new upper control arm, reconnect vacuum lines.

- Tighten silent block screws without the strut.

- Reinstall the strut, sway bar end link, and outer tie rod.

- Complete final tightenings using torque wrench.

- Put the wheels back on, lower the truck, and finish the operation.

FAQs

Can Leveling Kits be Causing the squeaking noise in your Ford F-150?

My friend experienced squeaking noise issue after installing a leveling kit on their F-150. Later it was found that the issue stemmed from brake caliper pins.

Final Thoughts

Once you’re done with these fixes, you won’t have to deal with your F150 squeaking on the road.

You can enjoy a smoother, quieter ride over any terrain as long as you maintain the parts, as I mentioned in the fixes above.

That’s all for this post. Enjoy your travels and stay safe!